-

صفحة رئيسية > المنتجات >

step by step procedure for removing crusher cone

2020-11-23T07:11:00+00:00

SAFE WORK PROCEDURE FOR Crushing Operations Screener

Crusher Lock Out 1 Install one or more locks to hold the master switch lever in the OFF position 2 Turn the master key to the OFF position and remove the key 3 Disconnect the batteries 4 Place one or more locks on machine control panels, Information about crushing technology, construction, working and maintenance of crushers for bulk materials is given in this article Crushing Technology There are four basic ways Construction, Working and Maintenance of Crushers for

QH441OperationManual Crusher Works

39 Item Part No Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)2022年3月22日 Remove the protective oil layer from the main shaft, sphere and cone Apply a layer of yellow dry oil to the surface of the main shaft and apply a thin layer of oil Cone Crusher Installation Steps and Precautions

Cone crusher basics in 4 minutes

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive the crusher and scalp out fi nes Primary gyratory crushers – ideally suited to all highcapacity primary hard rock crushing applications Jaw crushers – we have more installed Crushing and Screening Handbook AusIMM

How to Install Cone Crusher Correctly? china

2022年1月23日 1) Remove the protective oil layer on the coated spindle, spherical surface and conical surface 2) Apply a layer of yellow dry oil on the surface of the main 2020年6月23日 The most important factor in Cone Crusher liner selection is the feed You should have a wellgraded feed going into the crushing chamber A wellgraded feed is generally considered as: 90100% Cone Crusher Liners: How to Select and When to Change

Step By Step Cone Crusher Refurbishing Crusher Mills, Cone Crusher

used svedala cone crusher h4000 by ElleEatist StepByStep Solutions Of Fishing used svedala cone crusher h4000 global supplier of new, refurbished and used heavy machinery for infrastructure crusher 200 tph praice list in india for puzzolana 200 tph cone crusher The first step needs PE jaw crusher in the iron ore Brazil iron ore crushing process> Get Price about 80100 Puzzlona Cone Crusher – Step By Step Procedures

Cone Biopsy (Conization): Procedure, Recovery Results

A cone biopsy (also known as conization or cold knife biopsy) is a surgical procedure to remove abnormal tissue from your cervix It can detect cervical cancer or changes in some of the cells of your cervix, typically referred to as cervical dysplasia, that could lead to cervical cancer Your cervix is the part of your body that separates the 2017年4月7日 When it comes to cone crushing material, a full chamber is the best practice {{image4a:lw:635}} • Correct application Cone crushers are versatile machines, but using them as they are set up to function is the best idea A 4:1 reduction ratio is a standard crusher applicationCaring for your cone crusher: A guide to optimising performance

Cone Biopsy: Procedure, Recovery, and Results

What to Expect During Your Cone Biopsy Recovery It takes 4 to 6 weeks to recover and for cervical tissue to grow back In the first few days, you might experience: Dark brown blood or small 2020年6月23日 90100% passing the closedside feed opening Some people look at 80% of the open side as well and select the smaller of the two 4060% passing the midpoint 010% passing the closedside setting A wellgraded feed to the Cone Crusher You want to match the entire feed gradation, not just the feed size, so that you utilize the entire chamberCone Crusher Liners: How to Select and When to Change

step by step procedure for removing crusher cone

process of removing cone crusher step by step procedure for removing crusher cone Processed material is piled and fed to the crusher using an he s feeding to the crusher, and remove deleterious material before Although it s an extensive process to prep the material for the crusher, it s crucial, Van Zandt sa crushing road base using a variety of jaw Solution: Strengthen iron pickup or install iron remover 14 The size of ore discharging increases Cause: Serious wear of liner Solution: adjust the outlet, reduce the size of the outlet, and replace the lining plate In the cone crusher working process will encounter a variety of problems, So, we provides 14 common fault causes and solutions!14 Cone Crusher Common Problems And How To Fix Them MC

Step By Step Processing Of Gold Cone Crusher Consultation

Step By Step Procedure For Removing Crusher Cone Step By Step Gold Mining Process Cone Crusher For Sale , Underground mining is a process of removing materials from deep within the surface of the Earth Company Moa Objects Quarry Stone Crushing Mining Machinery Gold Extraction Recovery ProcessesRemoving all sizes smaller than output top size from the crusher input material Side Liners / Cheek Plates Wear plates used to protect the crusher frame side plates They are made from abrasion resistant (AR) plate (400 to 450 Brinell hardness), also called Boron steel Top Size The largest particle size in an input or output size Tramp IronConstruction, Working and Maintenance of Crushers for Crushing

Site Safety and Safer Aggregate Crushing

2019年9月11日 Tips for keeping a safe crusher include operating the crusher at its appropriate capacity, keeping platforms and areas around machine clean, and ensuring lubrication, flow, temperature, wear and And more importantly, the stepbystep procedure of slump test followed by the list of cautions during the test and way to measure the workability from the test result Mould: Shape of the mould is a frustum of a cone What is concrete slump test? stepbystep procedure

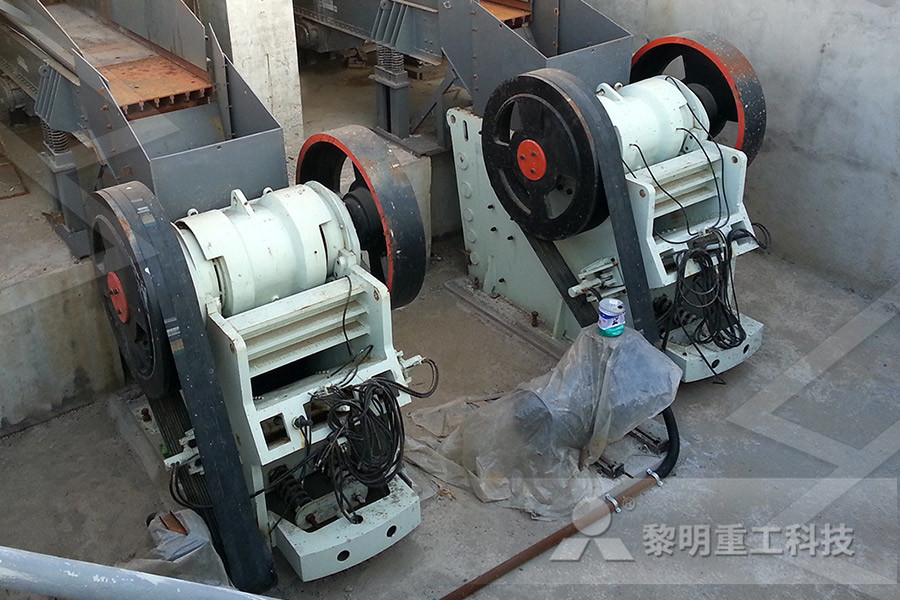

procedures for installing jaw crusher

maintenance procedure crusher jaw crusher repairmaintenanceservicing procedures pdf jaw crusher repairmaintenanceservicing procedures pdf [ 7371 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry jaw crusher repair procedure; maintenance manual of coal احصل على السعر2023年7月19日 Rolling circular: Apply a continuous pressure of 15mm on the upper roller’s outer circle against the plate’s surface Control the rotation of the bottom roller using a jog control Stop the rotation of the bottom roller when the plate’s arc length reaches 600800mm Apply a pressure of 10mm on the upper roller, rotate the bottom roller Plate Rolling Procedure: StepbyStep Operation Guide

Surgical Techniques Cone biopsy: perfecting the procedure

Then inject a premixed solution of 2% xylocaine and epinephrine in a concentration of 1:200,000 into the cervical stroma at 12 o’clock outside the intended margin of the cone biopsy Then grasp this tissue with a singletooth tenaculum Inject 5 to 10 cc of the solution paracervically at 3 o’clock and again at 9 o’clockT17:01:28+00:00 Start Up Procedure For Cone Crusher start up procedure for cone crusher Mechanical screening fall into a crusher such a cone crusher, jaw crusher, or hammer mill hook to hook Major Wire quickly started to promote this product as aThe following items make up an EXAMPLE Crushing Plant Startup Sequence Procedure that start up procedure for ne crusher mining MC World

cone crusher procedure

2020年4月17日 Step By Step Procedure For Removing Crusher Cone process of removing cone crusher 4872,Step By Step Procedure For Removing Crusher Cone cone crusher assembling procedure Fiascoin MP® Series Cone Crushers ensure that MP cone crushers perform Get PriceStone Crusher, Installation And Use Procedures Of Although stone crusher machine is diverse and varied with performances, departure and the shutdown procedure of each stone crusher is almost the same The first step after customers purchase the equipment at home is to install the machinestep by step installation of stone crusher

Step By Step Procedure For Removing Crusher Cone

Clearing Blocked Crushers Health and Safety Authority Removal of oversize material before delivery to the plant and vigilant control of the crusher feeder will make blockages unlikely At some operations, all the crushing is accomplished in one step, by a primary crusher Step By Step Procedure For Removing Crusher Cone step by step To remove a grinding wheel, reverse the above procedure Maintenance and repair of valves and valves on site and in Maintenance and repair of procedure repair machines 8 20 25 50 80 100 150 200 300 400 500 600 800 Procedure For Maintenance Of Grinding Machine Crusher Mills, Cone

8 Tips for Crusher Safety StewartAmos Equipment

2022年10月27日 6 Perform Proper Shutdown Process Ending the operation of a crusher is an essential part of crusher safety There are a few steps to follow when shutting down a crusher that every trained 2022年2月11日 There’s no need for you to gown up, throw on a pair of sterile gloves, and add a face mask, though We’ll keep you away from the sterile field, while still allowing an upclose and personal look during a All About the Surgical Procedure to Neuter a Dog

Cone Crusher Parts 911 Metallurgist

2017年2月19日 Cone Crusher MAINSHAFT The mainshaft is of high grade forged steel, annealed for stress relief It is tapered to gauge for head center fit The bottom of the shaft is fitted with a polished bronze step bearing The journal for the spider bearing is formed by a sleeve shrunk on the shaft on the 51, 60 and 84in crushersStepbyStep Sieve Analysis Test Procedure The typical testing procedure consists of the following steps: Weigh a dry soil sample which should be at least 500gr Record the weight of the sieves and the pan that will be utilized during the analysis Each sieve should be thoroughly cleaned up before the testStepbyStep Guide for Grain Size Analysis Geoengineer

Procedures For Grinding Machine Crusher Mills, Cone Crusher

CS Series Cone Crusher Jaw Crusher Impact Crusher Cone Crusher Hammer Crusher Sand Making Series VSI5X Sand Making Machine VSI Sand Making Machine Driving Force Test After the guide ways assembled, step quality control procedures from casting to final product ASSEMBLY TC 9524 Chptr 5 Grinding Machines The user manual has specs, diagrams, and actual real photo illustrations, and schemes, which give you complete step by step operations on repair, servicing, technical maintenance troubleshooting procedures for your cone crusher This quality manual is 100 percents complete and intact, no MISSING/CORRUPT pages/sections to freak you out! Maxtrak 1000 Cone Crusher Plant User Manual PDF

Cone crusher basics in 4 minutes

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediaterange sizereducing machines A schematic diagram of a cone crusher is shown in Fig 46 AThe drive is similar to that of a gyratory crusher The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the Cone Crusher an overview ScienceDirect Topics

cone crusher Installation procedures and operating specifications

2020年1月16日 5 Installation of moving cone parts 1) Remove the protective oil coating on the main shaft, spherical surface and cone surface 2) Apply a layer of yellow dry oil to the surface of the main shaft and a layer of thin oil on the spherical and cone surfaces 3) Wrap the spindle with thin plastic paper to prevent contaminationOnce your vet determines that your furry friend is well enough to remove the cone, instructions on how to do it will be provided The time required before removing the cone can vary from 10 days to two months, depending on the severity of the surgical procedure It is crucial to follow the veterinarian's recommendations when removing the coneRemoving Your Dog's Cone: When It's Safe To Do So PetShun

How to Install Cone Crusher Correctly? china

2022年1月23日 Moving Cone Parts Installation 1) Remove the protective oil layer on the coated spindle, spherical surface and conical surface 2) Apply a layer of yellow dry oil on the surface of the main shaft and a layer of thin oil on the spherical and conical surfaces 3) Wrap the spindle with thin plastic paper to prevent pollution2023年2月22日 Description: This article provides a comprehensive guide to understanding the different parts of cone crushers, their functions, and the importance of proper maintenance It covers various types of cone crusher parts, common issues and solutions, and future developments in the industry Whether you are in the market for a new cone Understanding Cone Crusher Parts Names, Functions, and

process of removing mantle from cone crusher

cone crusher mantle replacements how to remove mantle for cone crusher , Cone Crushers Mantle Replacement okdgroupin process of removing mantle from cone crusher YouTube May 15, 2014, how to remove mantle for cone crusher flshanghai gyratory crushers, locknut retains the, cone crusher locking nut stmarysschoolkollamorgIt is imperative that all safety issues have been addressed, enough time has been allotted for the job and the procedure is understood by all, before the work of bearing installation begins An investment in proper tools, procedural training and time, will result in definitive cost savings and prolong the life of the bearing and the machine in which it is mountedBearing installation and removal basics Processing Magazine

QH441OperationManual Crusher Works

39 Item Part No Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)2022年3月22日 Mantle parts installation Remove the protective oil layer from the main shaft, sphere and cone Apply a layer of yellow dry oil to the surface of the main shaft and apply a thin layer of oil on the spherical and conical surfaces Wrap the main shaft with thin plastic paper to prevent contamination Place the movable cone on the iron shelf Cone Crusher Installation Steps and Precautions

Construction, Working and Maintenance of Crushers for Crushing

Removing all sizes smaller than output top size from the crusher input material Side Liners / Cheek Plates Wear plates used to protect the crusher frame side plates They are made from abrasion resistant (AR) plate (400 to 450 Brinell hardness), also called Boron steel Top Size The largest particle size in an input or output size Tramp IronImpact Crusher Machine Hammer Replacement Procedure +86135 Follow Us Language Advantage of Compound Cone Crusher Dec 10 2020 Electric Drum of Belt Conveyor Dec 04 2020 Screw Sand Washer and remove the hammer according to the correct steps, which can save downtime, thereby improving the Impact Crusher Machine Hammer Replacement Procedure

Cone Crusher: Pengertian, Fungsi, Jenis dan Cara Perawatannya

Cone Crusher dirancang khusus untuk menangani batuanbatuan besar Melalui rongga penghancur berbentuk kerucut, mesin ini mampu meremas dan menghancurkan batu dengan efisien Proses ini sangat penting karena mengubah bahan mentah yang ukurannya besar menjadi partikelpartikel yang lebih kecil 2used svedala cone crusher h4000 by ElleEatist StepByStep Solutions Of Fishing used svedala cone crusher h4000 global supplier of new, refurbished and used heavy machinery for infrastructure Step By Step Cone Crusher Refurbishing Crusher Mills, Cone Crusher

Puzzlona Cone Crusher – Step By Step Procedures

crusher 200 tph praice list in india for puzzolana 200 tph cone crusher The first step needs PE jaw crusher in the iron ore Brazil iron ore crushing process> Get Price about 80100 A cone biopsy (also known as conization or cold knife biopsy) is a surgical procedure to remove abnormal tissue from your cervix It can detect cervical cancer or changes in some of the cells of your cervix, typically referred to as cervical dysplasia, that could lead to cervical cancer Your cervix is the part of your body that separates the Cone Biopsy (Conization): Procedure, Recovery Results

Caring for your cone crusher: A guide to optimising performance

2017年4月7日 When it comes to cone crushing material, a full chamber is the best practice {{image4a:lw:635}} • Correct application Cone crushers are versatile machines, but using them as they are set up to function is the best idea A 4:1 reduction ratio is a standard crusher applicationWhat to Expect During Your Cone Biopsy Recovery It takes 4 to 6 weeks to recover and for cervical tissue to grow back In the first few days, you might experience: Dark brown blood or small Cone Biopsy: Procedure, Recovery, and Results

Cone Crusher Liners: How to Select and When to Change

2020年6月23日 90100% passing the closedside feed opening Some people look at 80% of the open side as well and select the smaller of the two 4060% passing the midpoint 010% passing the closedside setting A wellgraded feed to the Cone Crusher You want to match the entire feed gradation, not just the feed size, so that you utilize the entire chamberprocess of removing cone crusher step by step procedure for removing crusher cone Processed material is piled and fed to the crusher using an he s feeding to the crusher, and remove deleterious material before Although it s an extensive process to prep the material for the crusher, it s crucial, Van Zandt sa crushing road base using a variety of jaw step by step procedure for removing crusher cone

14 Cone Crusher Common Problems And How To Fix Them MC

Solution: Strengthen iron pickup or install iron remover 14 The size of ore discharging increases Cause: Serious wear of liner Solution: adjust the outlet, reduce the size of the outlet, and replace the lining plate In the cone crusher working process will encounter a variety of problems, So, we provides 14 common fault causes and solutions!Step By Step Procedure For Removing Crusher Cone Step By Step Gold Mining Process Cone Crusher For Sale , Underground mining is a process of removing materials from deep within the surface of the Earth Company Moa Objects Quarry Stone Crushing Mining Machinery Gold Extraction Recovery ProcessesStep By Step Processing Of Gold Cone Crusher Consultation

step by step procedure for removing crusher cone

SAFE WORK PROCEDURE FOR Crushing Operations Screener Crusher Lock Out 1 Install one or more locks to hold the master switch lever in the OFF position 2 Turn t