-

صفحة رئيسية > المنتجات >

fabrication of ball mill conic

2023-01-22T23:01:22+00:00

Design and fabrication of a new micro ballend mill with

2018年3月27日 A practical grinding method is proposed based on the kinematic principle of the sixaxis computer numerical control () grinding machine for micro conical surface ballend mills and is validated by grinding simulations and experiments2018年6月16日 designing geometric structure and edge strength of micro ballend mills In this study, a new configuration of a micro ballend mill for micro dimple milling is Design and fabrication of a new micro ballend mill with

(PDF) DESIGN AND FABRICATION OF MINI BALL

2016年5月30日 This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder Ball mill is a 2018年7月1日 Design and fabrication of a new micro ballend mill with conical flank face Authors: Zhiqiang Liang Beijing Institute of Technology Shidi Li Tianfeng Zhou Beijing Design and fabrication of a new micro ballend mill with

Design, fabrication and performance analysis of mini ball miller

2021年1月1日 CMCs are prepared by powder metallurgy route due to its high temperature Powder metallurgy fabrication process involves three stages: mechanical alloying of 2018年6月16日 The experimental results show that the micro ballend mill with a 20° relief angle is more appropriate for micro dimple milling compared to the other two mills Micro Fabrication and milling performance of micro ballend mills

Design and Fabrication of a Simple Laboratory Ball Mill for

2018年11月1日 The laboratory ball mill consist of a steel bowl, steel ball and a vibrator The fabricated ball mill was tested to 1 mm, 10 mm and 110 mm of coconut shell chips Abstract Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical Ball milling: a green technology for the

Ball Mill an overview ScienceDirect Topics

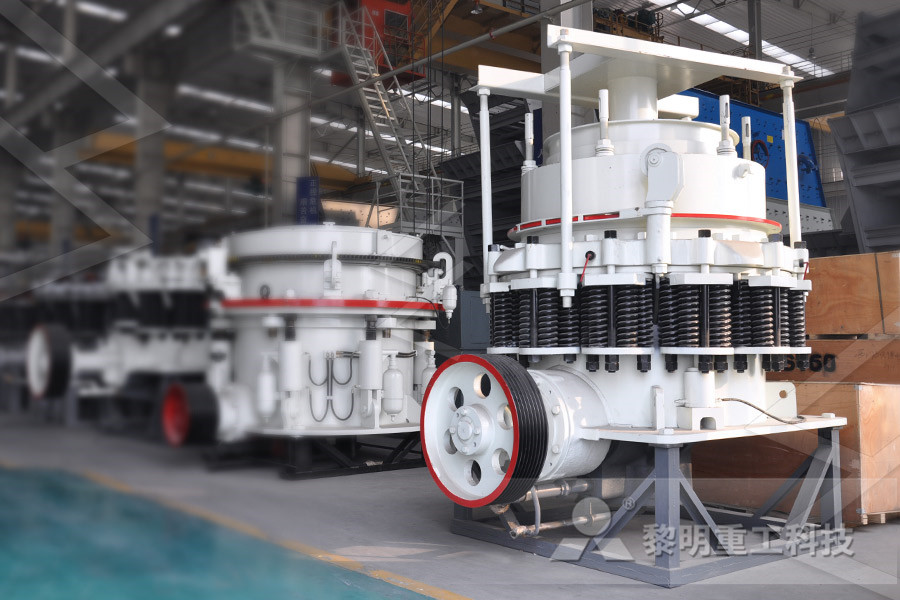

Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part located between them (Fig 212) Such a ball mill body is expedient Contribute to brblmd/ development by creating an account on GitHub/ fabrication of ball mill conic hardingemd at main

fabrication of ball mill conic hardinge

1 ton ball miller machine in greece price Ball Mill RETSCH powerful grinding and homogenization RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both 2018年6月16日 gy, the fabrication methods for micro mills are also diverse and include the use of wire electrical discharge machining (WEDM) [10], focused ion beam (FIB) [11], and laser beam forming However, precision grinding technology is still the main method for the fabrication of micro ballend mills with high efficiency and high flexibilityDesign and fabrication of a new micro ballend mill with

fabrication of ball mill nic equanta

Conical Ball Mill Design Fabrication of ball mill conic Hardinge conical ball mill mineral processing metallurgy grinding can be done either wet or dry, and on account of the conical shape of a hardinge mill, a positive discharge can be obtained without the use of internal screens, such as are employed with practically all high speed The geometry of a mill with conical ends is shown in Figure 86 The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (816) The density of the charge must account for all of the material in the mill including the media which may be Fabrication Of Ball Mill Conic ruta12es

Design and fabrication of a new micro ballend mill with

2018年3月27日 Micro ballend milling is an efficient method for the fabrication of micro lens array molds However, it is difficult to meet the machining quality of micro dimple molds due to the wear and breakage of the milling cutter, which presents large challenges for designing geometric structure and edge strength of micro ballend mills In this study, a new Fabrication of ball mill conic Hardinge conical ball mill mineral processing metallurgy grinding can be done either wet or dry, and on account of the conical shape of a hardinge mill, a positive discharge can be obtained without the use of internal screens, such as are employed with practically all high speed pulverizers and machines of the Fabrication Of Ball Mill Conic Hardinge burgenpsy

fabrication of ball mill conic hardinge

harding conical ball mill specifications Harding Conical Ball Mill Specifications Harding Conical Ball Mill Specifications The hardinge conical mill is the invention of mr hw hardinge and has been fully patented by him it has been used successfully in the grinding of ores limestone phosphate rock feldspar and talc the purpose of the tests in this thesis was to Contribute to naicha22/2022 development by creating an account on GitHub2022/ design and fabrication of ball mill pdfmd at main

Design Features Of Ball Millsfoundations for conic ball mill

DESIGN AND FABRICATION OF MINI BALL MILL ball mill foundations design criteria rrcserin Full text PDF on ResearchGate This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nano powderball mill foundations design criteria installed in both 40 SAG and 28 Ball mills Foundation design 2018年6月16日 gy, the fabrication methods for micro mills are also diverse and include the use of wire electrical discharge machining (WEDM) [10], focused ion beam (FIB) [11], and laser beam forming However, precision grinding technology is still the main method for the fabrication of micro ballend mills with high efficiency and high flexibilityDesign and fabrication of a new micro ballend mill with

Design, fabrication and performance analysis of mini ball miller

2021年1月1日 These forces are generated due to particle movement in the mill jar, the motion of balls and contact zones The ball milling design significantly depends on the size of mill jar, required particle size distribution of powder and grinding media (balls) [13], [14], [15] The main purpose of milling process is to obtain required particle size of the powder المخروطية الكسارة HPT BWZ سلسلة ساحة الثقيلة المغذية صممه GBM هي واحدةfabrication of ball mill conic

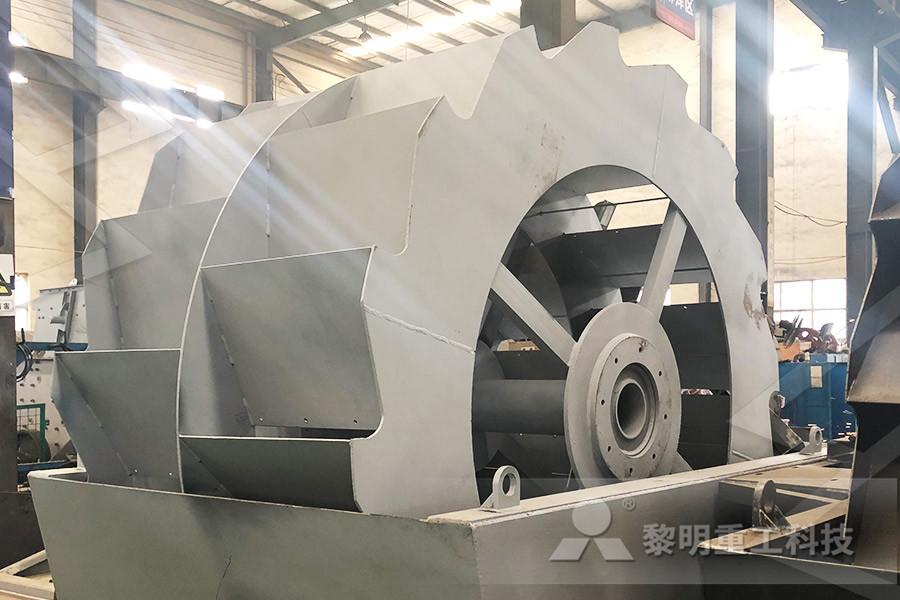

(PDF) DESIGN AND FABRICATION OF MINI BALL

2016年5月30日 A comparative study was carried out for an alloy of Al 50 (Ni 75 Mo 25) 50 processed by two different high energy ball mills A SPEX and Simoloyer mill were usedBall Mill Application and Design Ball mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor materials, nutraceuticals and pharmaceuticals materials down to 1 micron or less The residence time in ball mills is long enough that all particles get Ball Mill Application and Design Paul O Abbe

Fabrication of homogeneous nanosized nickel powders using

2021年4月1日 The dispersant was prepared using ZrO 2 balls 2 ф in size; the nickel particles were dispersed in a ball mill (GLBMG; Global Lab Co Ltd, Korea) and then mixed with an ethyl cellulose50 binder (Junsei Chemical, Japan) to create pastes with viscosity of 100–150 Pas using an ultrasonic processor (VCX500; Sonics Materials, USA) [22]2023年1月1日 In the investigation High energy planetary ball milling has beed employed to fabricate Aloe vera nanopowder From the microstructural (SEM) analysis of it is found that the average grain siz of the Aloe vera nanopartical varies between 46 nm and 127 nm In addition, it is also obtained that the average size of the Aloe vera nanoparticles Fabrication of Aloe vera nanopowder by high energy ball mill

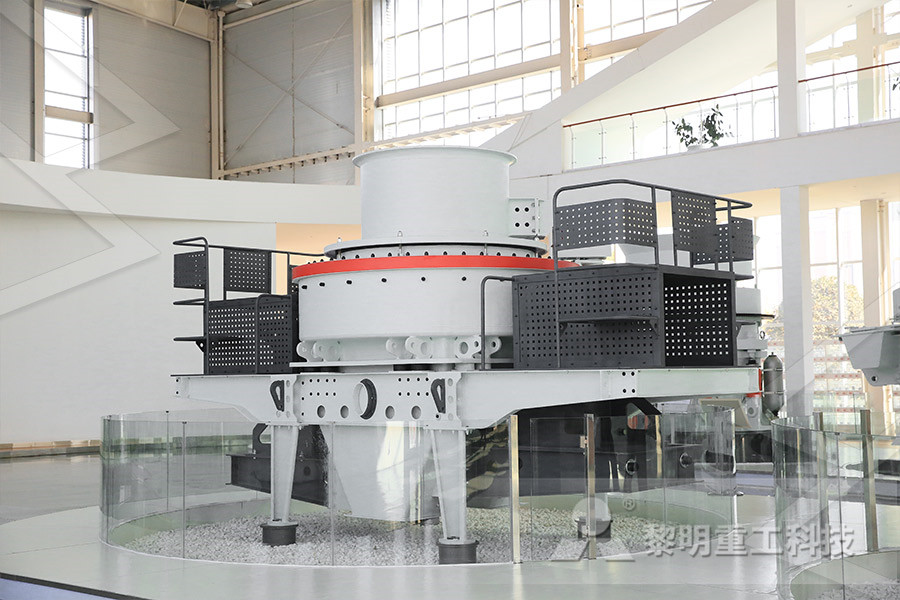

Industrial Application Of Ball Mill AGICO

BALL MILL APPLICATION Ball mill is a type of grinding equipment for fine pulverizing crushed materials It further reduces the particle size of raw materials, generally applied in the material pretreatment stage in industrial production lines Compared with other grinding machines, it makes full use of resources, reduces energy consumption 2021年1月1日 The ball milling design significantly depends on the size of mill jar, required particle size distribution of powder and grinding media (balls) [13], [14], [15] The main purpose of milling process is to obtain required particle size of the powder without any contamination, increasing the output of the milling circuit and overall reduction in Design, fabrication and performance analysis of mini ball miller

fabrication of ball mill conic sekstolarstwo

Ball Mill Fabrication Pdf Design And Fabrication Of A New Micro Ball In this study a new configuration of a micro ballend mill for micro dimple milling is designed and named the micro conical surface ballend millhe cutting edge is formed by intersecting the conical surface and the inclined plane ball mill fabrication mtd aldeabi84Ball 2018年7月1日 To investigate effective fabrication of a micro ballend mill with different relief angles, this paper proposes a practical grinding method for the relief face validated by a grinding experiment Design and fabrication of a new micro ballend mill with

Fabrication Of Ball Mill Conic wapnodolokorn

Fabrication Of Ball Mill Conic hfbiorevitaltherapeut Fabrication Of Ball Mill Conic fabrication of the ball mill grinding test was conducted with the mill using limestone as the feed material this was followed by the particle size analysis of the ground product from the mill in design construction and performance analysis of a 5The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials 18 Being an environmentallyfriendly, costeffective technique, it has found wide Ball milling: a green technology for the

Fabrication of polymer nanocomposites via ball milling: Present

2017年5月1日 Ball milling is based on the occurrence of collisions between the milling tools inside a batch reactor that contains materials in powder form [66], [67], [77], [81]The collisions are a consequence of the reactor, or a part of it, moving [77], [81]During each collision, a fraction of the powder is trapped between the colliding surfaces and subjected 2021年4月1日 A microsized nickel oxide powder was milled to uniform size (1832 ± 538 nm) using a planetary ball mill; the size distribution was more uniform than that of a commercial powder (4002 ± 1834 nm) The sintering characteristics and capacitive features of the powders were analyzed after reduction in hydrogenFabrication of homogeneous nanosized nickel powders

Design and fabrication of a new micro ballend mill with

2018年3月27日 Micro ballend milling is an efficient method for the fabrication of micro lens array molds However, it is difficult to meet the machining quality of micro dimple molds due to the wear and breakage of the milling cutter, which presents large challenges for designing geometric structure and edge strength of micro ballend mills2018年12月3日 The laboratory ball mill consist of a steel bowl, steel ball and a vibrator The fabricated ball mill was tested to 1 mm, 10 mm and 110 mm of coconut shell chips for three series of testing to evaluate the grinding capability and reproducibility For 30 minutes of testing, the ball mill has produce the powder coconut shell about (2607 ± 12 Design and Fabrication of a Simple Laboratory Ball Mill for

DESIGN AND FABRICATION OF MINI BALL MILL

Mechanical System Design, 25 Mar 2016 Universiti Malaysia Pahang, Pekan, Malaysia DESIGN AND FABRICATION OF MINI BALL MILL Rutheravan Maria 1Automotive Engineering Research Group (AERG), Faculty 2017年4月10日 6 ft by 16 in ball mill Capacity, 150 tons per 24 hr, average of nine months Charge, 4 tons of balls Speed, 28 rev per minute Horsepower, 36 Water, 15 tons KCN solution to 1 ton of dry ore Elevation of feed end, 125 in Consumption of balls, 05 lb per ton of ore Feed to mill through 2in meshHardinge Conical Mill Capacity 911 Metallurgist

fabrication of ball mill conic hardinge

Fabrication Of Ball Mill Conic Fabrication Of Ball Mill Conic The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter Figure 811The feed can be dry with less than 3 moisture to minimize ball coating or slurry containing 20–40 water by weight

fabrication of ball mill conic

Design and fabrication of a new micro ballend mill with 2018年3月27日 A practical grinding method is proposed based on the kinematic principle of the sixaxis co